Thousands of Great Deals Every Day

100's of New Products

Great savings on closeout and overstock items. New items added regularly. Limited Quantities

Free Shipping

On orders over $250.00 (with destinations in the lower 48 contiguous states)

Best Offers

Low prices every day on name brand products

Top Quality

Offering only the best, most reliable and top performing product brands

Worldwide Shipping

International shipments processed every day

Volume Discounts

Volume or tiered pricing on many products

Secure Ordering

Highest levels of security when placing an order and protecting customer data and privacy

Crate Engines

Popular crate engines from BluePrint and LS Classic. Including Chevy Small and Big Block, GM LS Series, and Small Block Ford.

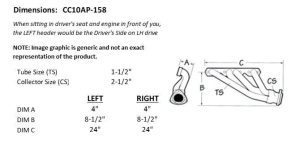

Exhaust System Components

Headers, Mufflers, Cat-Back Kits, Catalytic Converters, Exhaust Cutouts, Exhaust Tips

Featured Products

-

$615.95Original price was: $615.95.$559.95Current price is: $559.95. Add to cart -

$758.95Original price was: $758.95.$689.95Current price is: $689.95. Add to cart

Guaranteed Power and Reliability

Crate Engines

Choose from Chevy Small Block, Big Block, GM LS, and Ford Small Block engines. Standard or stroked, short blocks to complete carbureted or fuel injected.